New Types of Nanodiamonds

Despite the expanding research interest, detonation nanodiamond (left: detonation nanodiamonds on HiPco single wall carbon nanotubes) is nearly the only one kind of nanodiamond available on the market even for researchers, except the ones larger than 50 nm. What we can easily get is nearly spherical 5 nm big detonation nanodiamonds containing about 2 at% of nitrogen. The aim of our study is to produce new types of nanodiamonds, for example, metallic nanodiamonds, magnetic, anisotropic, etc., for further development of sp3 nanocarbon-based technology.

detonation nanodiamond (left: detonation nanodiamonds on HiPco single wall carbon nanotubes) is nearly the only one kind of nanodiamond available on the market even for researchers, except the ones larger than 50 nm. What we can easily get is nearly spherical 5 nm big detonation nanodiamonds containing about 2 at% of nitrogen. The aim of our study is to produce new types of nanodiamonds, for example, metallic nanodiamonds, magnetic, anisotropic, etc., for further development of sp3 nanocarbon-based technology.

As tuning the electronic properties of diamond is possible by doping of electron donors or acceptors, the point for the production of electronically modified nanodiamonds seems to be how to reduce the size of doped diamond or how to dope to nanoparticles of diamond. On the other hand concerning anisotropic nanodiamonds, some fascinating results have been recently disclosed. Diamond nanorods were found in 2004 to form from multi-wall cabon nanotubes when they are irradiated by hydrogen plasma. Several years later, thicker but much longer diamond wires were successfully produced in a commonly used tubular furnace at 900 ˚C under a CVD (chemical vapor deposition) condition very similar to that for carbon nanotube production. Though both cases are still at the microscopic scale, we see the light comimg after fullerenes, nanotubes, and graphenes. Our preliminary attempts are proving the results of the reports.

Buildup of Nanodiamonds: Bulk Diamonds and Composites

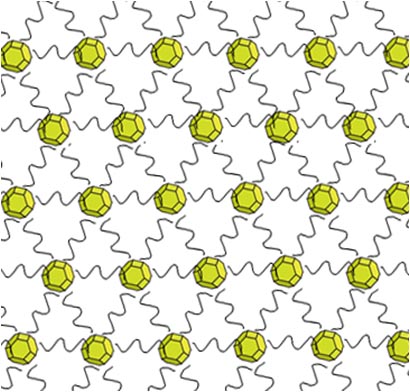

A diamond table or a chair is just a dream. This is because of the difficulty to grow such big crystals as well as to process them into desired shapes. However, it might become possible with tiny diamonds. When the size of a diamond particle decreses, it turns dispersive in liquid media. At the same time, the increased surface area of the particle makes chemical tuning of the surface fruitful. Now we have a chance to build up a chunk of diamond out of diamond particles. Particles might be bound together by covalent bondings or by electrostatic forces. If the linker gets bigger, the product might be called as a composite.

Concerning diamond, nanodiamonds have been available on markets, and which disperse well in liquid media depending on their surface terminating groups. In general, surface modification of such nanoparitcles is challenging, because they agglomerate easily upon addition of reagents, pH variation, heating, etc.. BASD technique, which we developed recently, solves this problem. Based on this technique, we are tackling building a bulk diamond or composite by bottom up approach.

available on markets, and which disperse well in liquid media depending on their surface terminating groups. In general, surface modification of such nanoparitcles is challenging, because they agglomerate easily upon addition of reagents, pH variation, heating, etc.. BASD technique, which we developed recently, solves this problem. Based on this technique, we are tackling building a bulk diamond or composite by bottom up approach.

日本語

日本語