Surface Functionalization of Agglomerating Nanoparticles

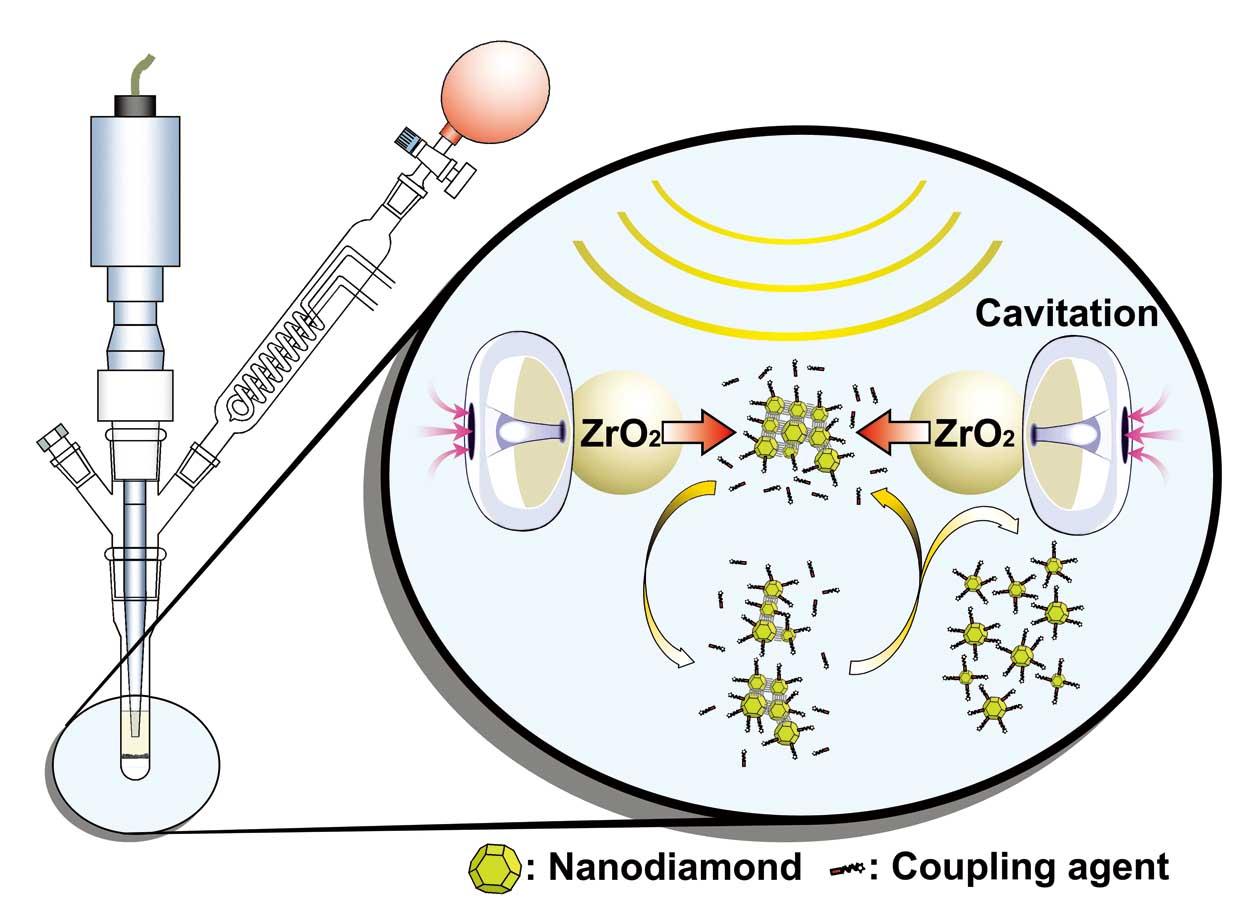

We propose a new method for surface chemistry of nanomaterials agglomerating in solvents. Crushing ability of powerful ultrasonication gets much stronger in the presence of hard ceramic beads than an ultrasonic treatment only. This bead-assisted sonic disintegration (BASD), which is likely caused by collisions between the beads propelled by ultrasonic cavitation, has a crushing capacity of equivalent or more than stirred media milling. The largest difference from stirred media milling is the simplicity of the device. Indeed, it can be easily integrated in the conventional glasswares  for wet chemistry (right: Functionalization of agglomerating nanoparticles using BASD. The deagglomeration process exposes fresh surfaces of primary particles to the coupling agents), and allows both breaking up of persistent agglomerates and surface functionalisation at the same time. This new technique is expected to work for nanoparticles like as a magnetic stirring bar for soluble compounds.

for wet chemistry (right: Functionalization of agglomerating nanoparticles using BASD. The deagglomeration process exposes fresh surfaces of primary particles to the coupling agents), and allows both breaking up of persistent agglomerates and surface functionalisation at the same time. This new technique is expected to work for nanoparticles like as a magnetic stirring bar for soluble compounds.

Reality, however, is not that simple. Unlike conventional compounds, nanoparticles are usually insoluble in any solvents. Homogeneous functionalization is limited to rare cases, where particles stay dispersed throughout reactions. This general behavior had been preventing surface chemistry of nanomaterials from remarkable development.

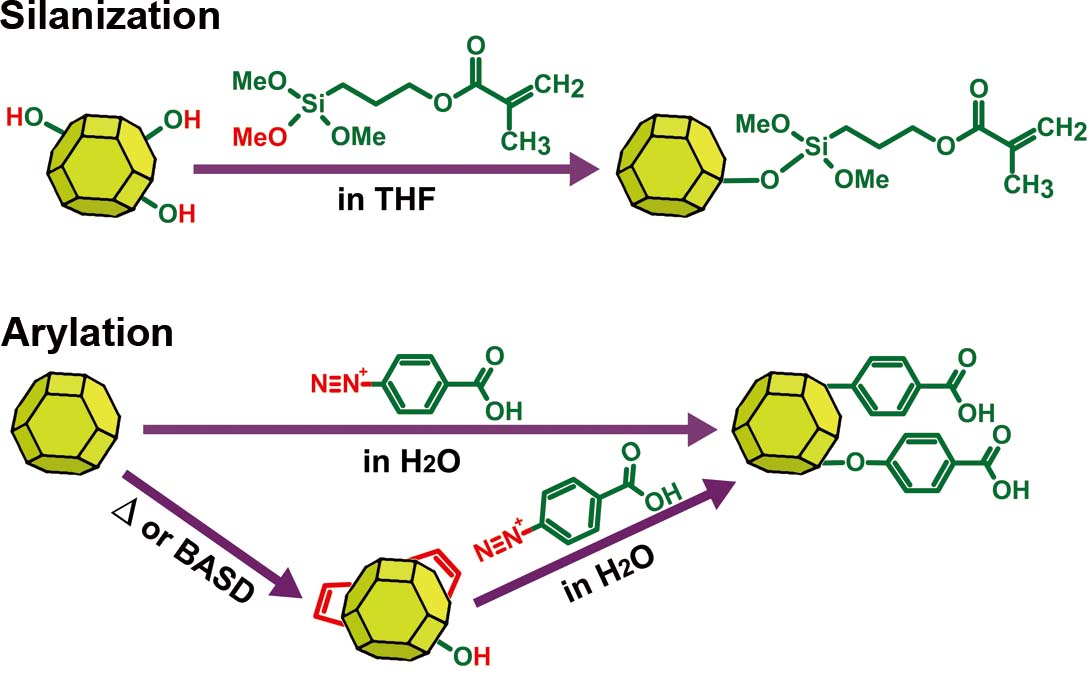

cles performed on agglomerates of nanodiamonds. Condensation reaction gave silanization, whereas arylation was carried out using diazonium salts), which are unable to be deagglomerated in the absence of beads. Functionalization of deagglomerated particles was verified in two different reaction systems.

cles performed on agglomerates of nanodiamonds. Condensation reaction gave silanization, whereas arylation was carried out using diazonium salts), which are unable to be deagglomerated in the absence of beads. Functionalization of deagglomerated particles was verified in two different reaction systems. |

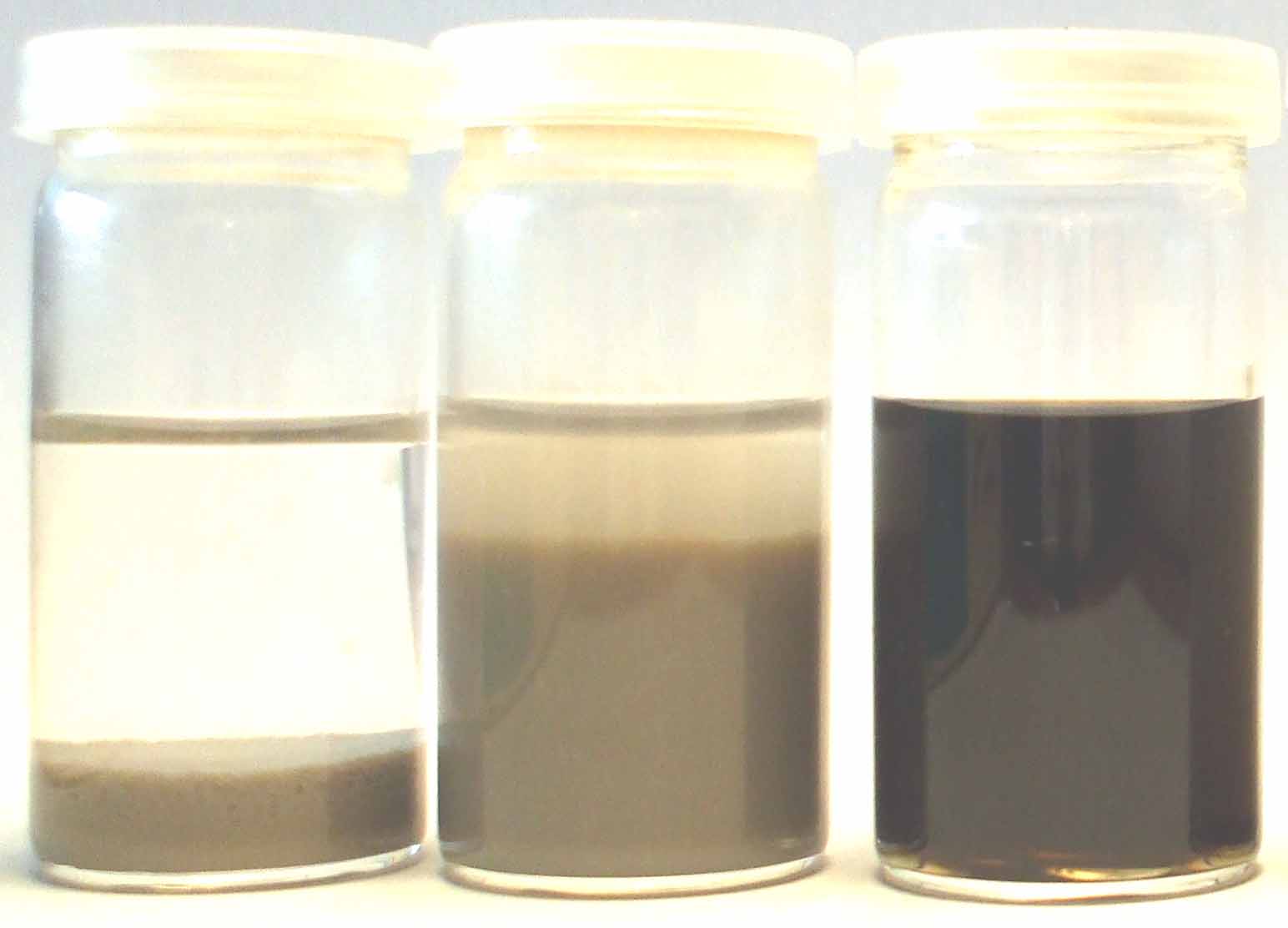

Left: Silylated nanodiamonds in THF. Nanodiamonds were sylilated using the commonly used magnetic stirring bar (left), ultra sonication (center), and BASD (right). Only the ones with BASD disperse well in THF, implying silylated surfaces of the primary particles. |